World Class Textile Producer with Impeccable Quality

World Class Textile Producer with Impeccable Quality

Great design is only half the battle. To build a successful fashion brand, you need a manufacturing partner who can bring your vision to life—without compromising on quality or ethics. Manufacturing is not a "one-size-fits-all" game. A factory that excels at producing thousands of basic T-shirts in China might be the wrong choice for a brand looking for small-batch, hand-woven alpaca wool from South America. Similarly, a denim specialist in Turkey operates very differently from an activewear expert in Australia.

To help you navigate this complex global landscape, we have curated a list of 8 distinct, reliable clothing manufacturers from around the world. We moved beyond the generic "top lists" to highlight manufacturers with specific strengths—whether you need premium denim, sustainable organic cotton, ethical swimwear, or rapid "Made in USA" production.

Quick Browse:

If you are looking for a manufacturing partner that combines the scalability of Chinese production with the attention to detail of a boutique studio, Runtang is a top contender. While many factories pigeonhole themselves into a single category, Runtang has built a reputation for versatility, handling everything from intricate woven garments to premium knits.

Located in a key textile hub, Runtang offers a true "one-stop" solution. This is particularly valuable for growing brands that want to expand their product lines (e.g., moving from just t-shirts to jackets and trousers) without having to source and vet three different factories. Their approach is consultative, meaning they work closely with clients to optimize costs without sacrificing fabric quality or construction standards.

Key Highlights:

If your brand’s aesthetic screams "summer vacation," "boho-chic," or "mindful living," Yogi & Boo is the perfect geographic and stylistic fit. Located in Bali, a region famous for its textile artistry, this manufacturer focuses heavily on ethical production practices and sustainable materials.

Unlike massive industrial factories, Yogi & Boo operates with a focus on craftsmanship. They are particularly renowned for their work with lightweight, breathable fabrics like rayon, linen, and bamboo, as well as high-quality swimwear. They are transparent about their staff's working conditions, which is a significant selling point for brands that market themselves on ethical grounds.

Key Highlights:

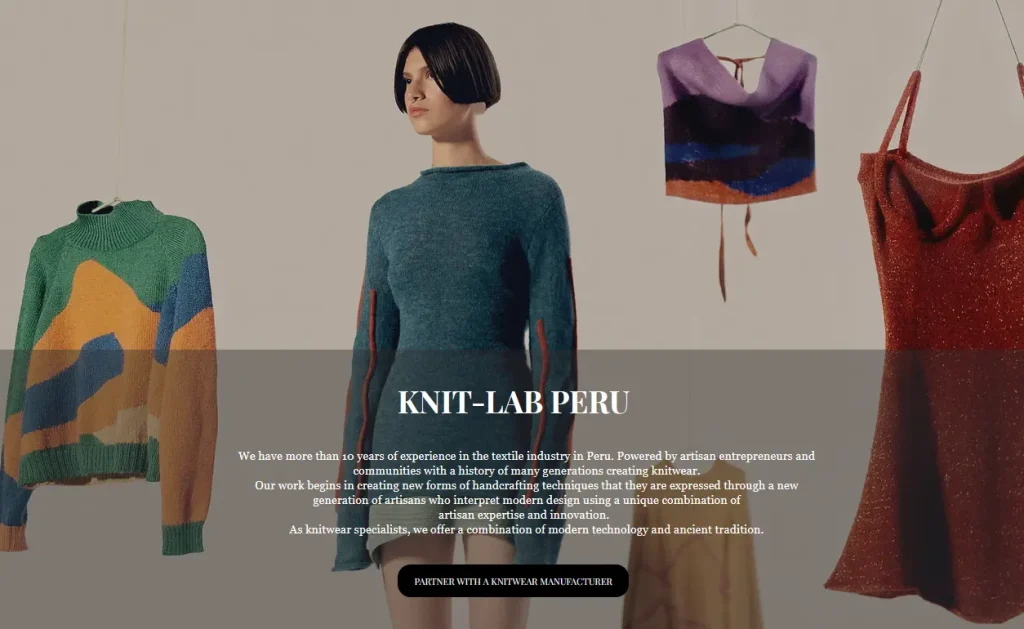

If your brand is positioned in the "affordable luxury" or high-end market, sourcing from generic textile mills won't cut it. KnitLab Peru offers something truly special: access to Peru’s legendary textile heritage. They specialize in fibers that define luxury: Royal Alpaca and Pima Cotton.

KnitLab acts as a bridge between modern fashion brands and traditional Peruvian artisans. They are not the place to go for cheap, fast-fashion sweaters; rather, they are the partner for brands creating "investment pieces." Their capabilities range from fine gauge machine knitting to hand-finishing, providing a level of texture and quality that is difficult to replicate elsewhere.

Key Highlights:

Denim is notoriously difficult to manufacture well. It requires heavy-duty machinery, specialized washing facilities, and a deep understanding of fit. Sarp Jeans, located in Turkey (Europe’s denim capital), is a manufacturer that simplifies this complex process for brands.

While many denim factories require massive minimums, Sarp is more agile, catering to brands that prioritize quality washes and modern fits over sheer volume. They are particularly relevant for the modern market because of their focus on sustainability. Denim production is traditionally water-intensive, but Sarp utilizes eco-friendly technologies like laser distressing and ozone washing to reduce environmental impact—a massive selling point for eco-conscious fashion labels.

Key Highlights:

For brands targeting the US market, the logistical nightmare of overseas shipping can sometimes outweigh the cost savings. Estilo Apparel, located in the heart of Los Angeles, offers a domestic solution. They are a premier "cut and sew" manufacturer that allows brands to proudly sew a "Made in USA" tag on their garments—a powerful marketing tool for certain demographics.

Estilo is known for its agility. While overseas production often requires months of lead time, domestic production can significantly shorten the cycle from design to delivery. This is crucial for trend-driven brands that need to react quickly to market changes. They offer comprehensive services including pattern making, sample sewing, and volume production, all under strict US labor standards.

Key Highlights:

Hingto has positioned itself as the go-to partner for fitness influencers and gym owners who want to launch their own lines. Based in Australia, they understand the western "athleisure" lifestyle better than most traditional factories.

Hingto operates with a unique hybrid model: they have an Australian headquarters for communication and design, with production facilities in China to keep costs competitive. They are famous in the industry for their "squat-proof" fabrics and performance testing. Whether you need a simple white-label solution (adding your logo to existing designs) or a fully custom cut-and-sew collection, they have a streamlined process for both.

Key Highlights:

While Peru is famous for Pima cotton, India is the undisputed heavyweight champion of the global organic cotton trade. Organic and More, based in Noida, India, is a manufacturer that doesn't just treat sustainability as a buzzword—it is their entire business model.

They are fully GOTS (Global Organic Textile Standard) certified, which is the highest validation a factory can achieve for organic processing. This makes them the perfect partner for brands targeting the "Eco-Mom" demographic (baby clothes) or the wellness market (yoga wear/loungewear). Unlike many Indian factories that focus on high-volume fast fashion, Organic and More caters to small and medium-sized ethical brands, offering transparency that is hard to find elsewhere in the region.

Key Highlights:

Starting a fashion brand can be intimidating, especially when technical packs and fabric sourcing come into play. Hawthorn International has carved out a unique space in the industry by catering specifically to this need. Based in London, they bridge the gap between a design agency and a manufacturer.

Hawthorn is an excellent choice for entrepreneurs who have a vision but might lack the technical background in garment construction. They offer a high level of support during the pre-production phase, helping to refine designs and select fabrics. While their production costs may be higher than pure Asian sourcing, the value they add through accessibility and lower Minimum Order Quantities (MOQs) makes them a favorite for new labels testing the market.

Key Highlights:

| Manufacturer | Location | Key Specialty | Best For | Unique Advantage |

| Runtang Textile | China | Comprehensive Full-Category | Scalable Brands & Diverse Lines | One-stop solution with cost-effective scalability. |

| Yogi & Boo | Indonesia (Bali) | Resort Wear & Swimwear | Ethical & Summer Brands | Expertise in digital printing and soft fabrics (Rayon/Linen). |

| KnitLab Peru | Peru | Luxury Knitwear | High-End Boutiques | Access to premium Alpaca and Pima Cotton fibers. |

| Sarp Jeans | Turkey | Premium Denim | Jeans & Casual Brands | Advanced sustainable washing tech (Ozone/Laser). |

| Estilo Apparel | USA (LA) | Domestic Cut & Sew | "Made in USA" Labels | Fast turnaround times and easy communication. |

| Hingto | Australia | Activewear & Sportswear | Fitness Influencers | Specialized in performance and "squat-proof" fabrics. |

| Organic and More | India | Organic Cotton | Eco-Brands & Baby Wear | GOTS certified factory focused on sustainability. |

| Hawthorn International | UK | Small Batch Production | Fashion Startups | Low MOQs and extensive design support. |

Before you commit to a production run, it is crucial to verify that the manufacturer aligns with your brand’s standards. Use this 4-point checklist:

1. Check the MOQ (Minimum Order Quantity): Does their minimum requirement match your budget? Some factories require 500 pieces per style, while others (like Hawthorn or Runtang) may offer more flexibility for startups.

2. Request Samples First: Never go straight to bulk production. Ask for a "proto-sample" to check the stitching quality, fabric hand-feel, and fit.

3. Ask About Lead Times: Fashion is time-sensitive. Clarify the turnaround time for both sampling (usually 2-4 weeks) and bulk production (usually 4-8 weeks).

4. Compliance & Certifications: If sustainability is your selling point, ask for proof. Do they have GOTS certificates (like Organic and More) or ISO accreditations?

What is a "Tech Pack" and do I need one?

A Tech Pack (Technical Packet) is a blueprint of your garment, including measurements, fabrics, and sketches. Most professional manufacturers require one to give you an accurate price quote.

Can I start a clothing line with a small budget?

Yes. Look for manufacturers that specialize in "Small Batch" production or "Low MOQ." Alternatively, consider "Private Label" (like Sarp Jeans) where you customize existing designs to save on development costs.

How long does it take to produce clothing from a manufacturer?

Production cycles vary due to multiple factors, including: order size, design complexity, manufacturer capacity, and certain seasonal factors. Generally, the production cycle for small orders is 2-4 weeks, while larger, more complex batch production requires a longer timeframe.

How can I manage costs when working with manufacturers?

Can I work with manufacturers from different countries?

Yes, successful brands often diversify their supply chain to leverage regional specialties. For instance, you might source premium knits from Peru while manufacturing high-volume basics in China. This strategy optimizes quality and risk, though it requires managing multiple timelines and shipping logistics.