World Class Textile Producer with Impeccable Quality

World Class Textile Producer with Impeccable Quality

For these last two decades, China has solidified its position in the global market as the most versatile and dependable sourcing location for polo shirts. With the ability to produce a diverse range of textile/cotton products and having a fully integrated textile ecosystem that comprises yarn and fabric knitting, dyeing, and garment stitching, to quality assurance and global logistics, these complete systems enable polo shirt manufacturers in China to excel in every aspect of the polo shirt manufacturing value chain. It is for this reason that businesses from all sectors, including fashion, sportswear, corporate uniform and promotional products, buy polo shirts from Chinese manufacturers.

The polo shirt itself has undergone a dramatic evolution, from a single type of cotton shirt with a collar to polyester and other high-tech, moisture-wicking fabrics blended with cotton and even eco-friendly, recycled fibers, to soft, high-quality combed cotton used for ultra-premium shirts. The ability to provide a diverse range of high-tech fabrics enables buyers to select the fabric and style that best suits their specific target market and price point.

Next, the guide will recommend eight of China's top polo shirt manufacturers, providing you with some valuable references.

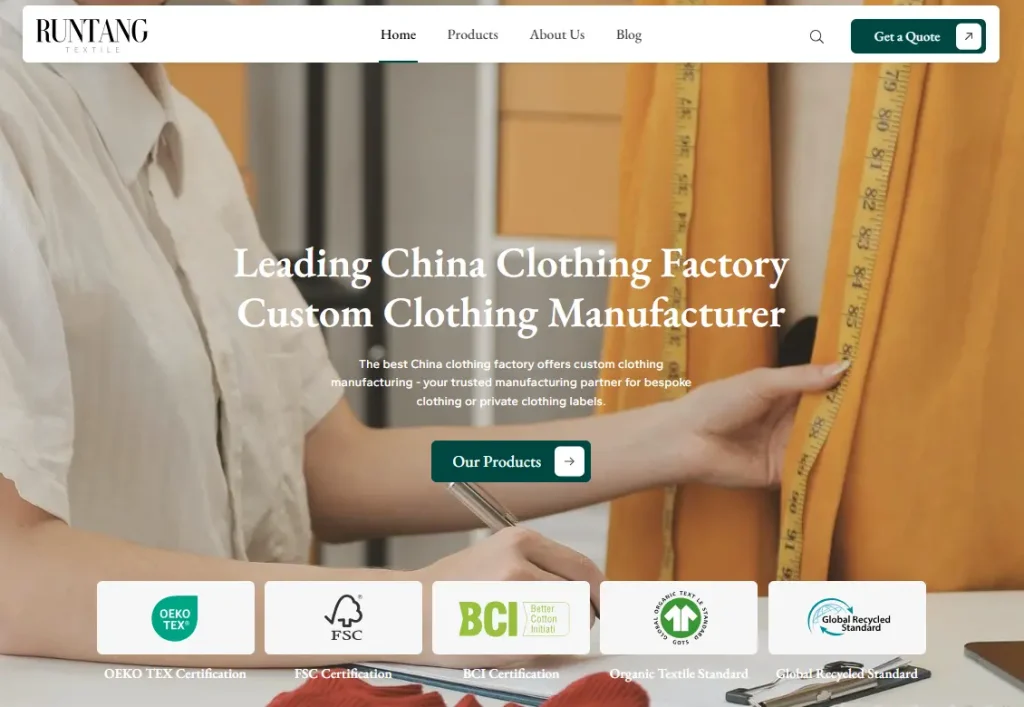

With their global buyers, Runtang Textile coordinates the production of high-quality polo shirts in accordance with their scale and capabilities. Their production line is integrated with the latest technology and staffed by experienced professionals. This cuts operating costs and enables efficient production from fabric selection to the final stitch. Their clients include brand-name companies, uniform suppliers, and retailers who are looking for reliable manufacturers with stable production capabilities.

Runtang has the capacity to manufacture polo shirts using various fabric materials, such as cotton pique, polyester blends, moisture-wicking knits, and other breathable performance materials. Their long textile history enables their buyers to select materials based on the comfort, durability and price range desired. Quality of the yarn, fabric construction, density, and even colourfastness are all controlled to ensure durable polo shirts are produced for all professional and leisure occasions.

Runtang Textile Company is able to accommodate small as well as large orders. Flexibility is built into the Runtang production system, allowing for rapid changes to be made to fabric type and colour, design, and logo placement. This system of responsiveness helps to satisfy new brands that are in the sample testing stages, as well as those in the established phases of their business, who are looking for bulk orders multiple times throughout the business year.

This firm has well-defined and automated operational systems that enable the firm to communicate effortlessly with clients and track the progress of orders, so they can send clients production and shipping updates. The firm's operational systems allow the firm to provide clients with automated, predictable shipping. This, in turn, allows the clients to integrate the firm's products into their systems more easily, especially clients based in other countries.

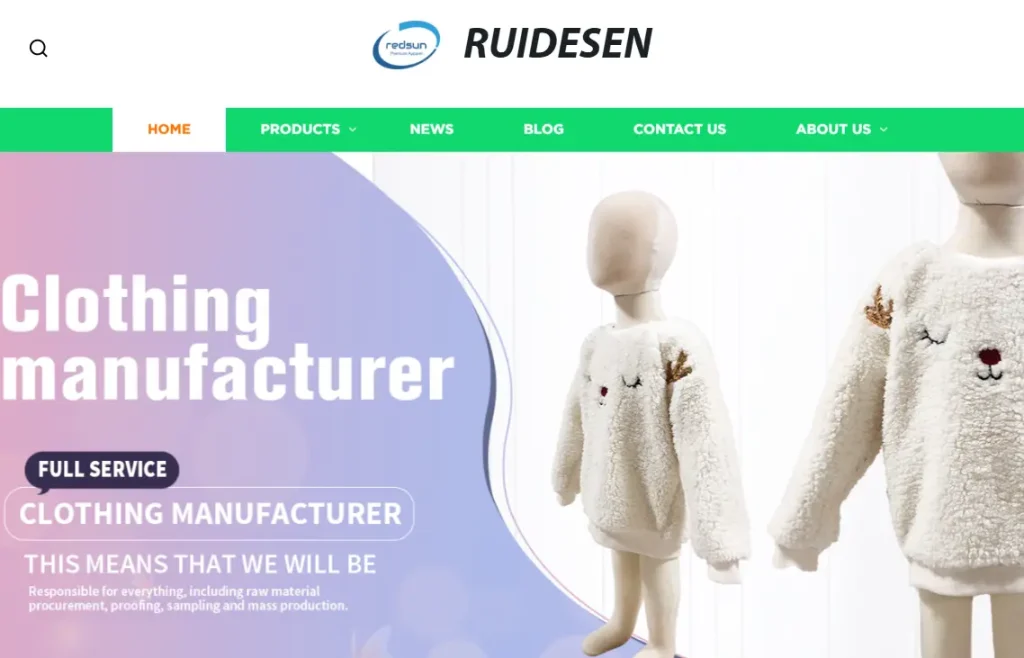

Ruidesen Apparel is a clothing manufacturer and has a primary focus on making bulk, customised apparel, specifically, polo shirts, and other active/work/sports uniforms. The firm is known for being able to provide reliable clothing solutions across several industries with adequate, if not impeccable, workmanship. The firm’s production facilities are well-equipped and are able to provide a variety of finishes to the clothes.

Ruisdeseb Apparel pays more attention to its selection of fabrics than other manufacturers. This includes cotton, pique knit, polyester blends with rapid-dry technology, and other fabrics used for performance activewear. The manufacturer has quality control systems in place, and they are strict for every piece of fabric and every stage of production. This includes quality control on fabric, stitching, and colour across the clothing.

Ruidesen Apparel has a lot of variety in the colour, embroidery, design, sleeve, collar, and printing of their clothing. Their sewing systems can handle more than standard designs of polo shirts, so their clients do not have to settle for just the basic designs that are more uniform. The firm can provide clients with clothing that is more aligned with their expectations. Advantages in Timely Delivery and Collaboration. The company has built a reputation for being responsive in tracking orders and communication, resulting in long-lasting collaborative partnerships with international buyers. Given the stability of the company’s supply chain structure, customers are provided with a seamless experience.

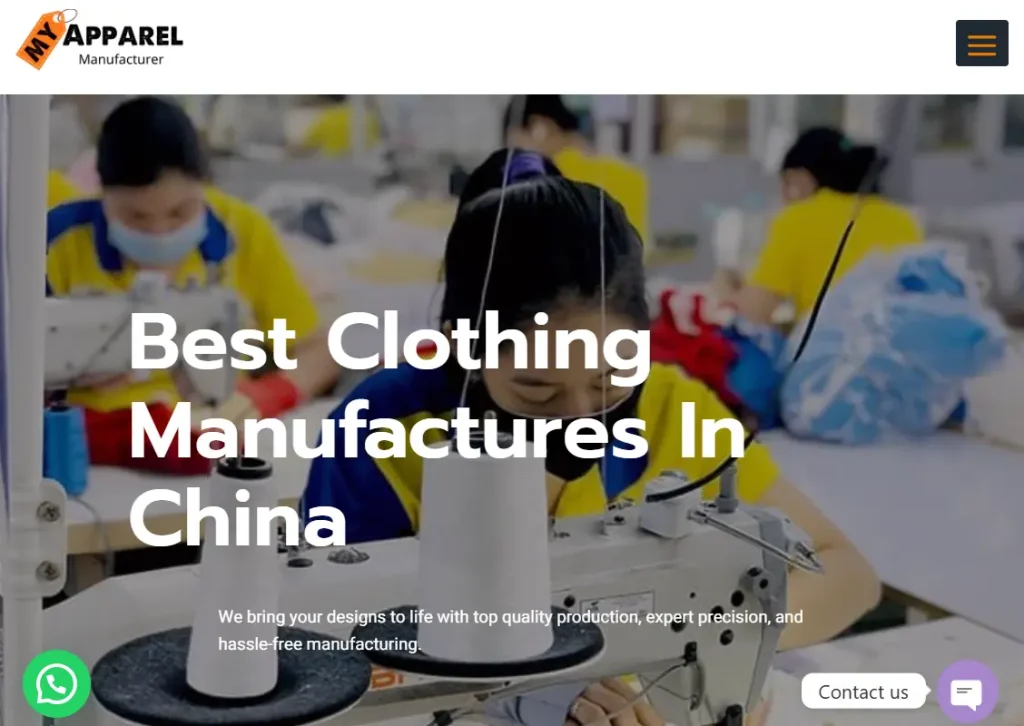

My Apparel Manufacturer is a company specialising in private-label apparel production, including polo shirts. This company works with both new ventures and established brands, providing development services, sampling, and professional garment construction. The manufacturer offers a selection of fabrics provided by reliable textile mills. Their team has the experience to construct polo shirts in a variety of fabrics, including cotton knit, blended polyesters, honeycomb, and performance fabrics, with a focus on durability and comfort. Technical expertise involves, but is not limited to, careful stitching, smooth seam construction, and collar rounding.

With respect to the industry, My Apparel is consistent in providing low minimum order quantities and fast sample development, allowing brands to go to market rapidly. Their production model allows for flexibility in meeting customer demands. Custom orders involve embroidery and woven labels, fit modifications, and design tweaks. Central to the operations of the organisation are the communication and updates. Communication of the fabric acquisition and inspections is covered and communicated to the consumers, ensuring transparency. This transparency leads to strengthened partnerships for the customers.

Tonton Sportswear manufactures sportswear and polo shirts for sports and organisational team wear. The organisation caters to sports associations and fitness companies, as well as event coordinators and companies for custom wear.

Toton has a wide variety of performance fabrics to include moisture-drying polyester, mesh, and quick drying. The fabrics are suitable for active environments, thus implies that buyers looking for light-weight, durable, and moisture-cutting fabrics are appropriate.

Tonton Sportswear accommodates a variety of order quantities, making it suitable for custom team uniforms or sportswear for a large-scale collection. The buyer has the option to control the styles, graphics, and logos that are incorporated on the items and thus makes the organisation appropriate for events or specific seasonal designs.

Toton sportswear has a set of quality control procedures to keep in check the quality of the performance contracts, in particular the athletic performance wear in keeping in mind the requirements of the pieces and the pieces with need for performance to keep the designs and the bodies intact. The company has a set of documented formal procedures for packing and transporting to help facilitate quick transport to the clients across the globe.

RunxM is a clothing manufacturer specialising in the design and production of polo shirts and other casual and sports clothing for international markets. The company has a commendable balance of technology, experienced personnel, and organised production structures.

The manufacturer uses specialised fabrics like dry-fit polyester, breathable mesh knits, and lightweight cotton blends. These materials are selected for their comfort, breathability, and durability, making them effective for daily wear and outdoor activities.

RunxM has adaptable production systems allowing for scale. Buyers can make small test orders and follow up with larger, repeating orders. The company’s production systems are agile and can add new design changes, bulk colour shifts, and rapid changes to pattern sets, all without reducing speed to market. The company has in place clear and visible production processes, starting with fabric inspections and concluding with final quality checks. Documented and consistent processes are the foundation of the trust the company has among its international clients.

Junesty focuses on casual wear and custom apparel. They hold a strong position in the polo shirt market. The company works with private label businesses, fashion brands, and uniform suppliers that require high-quality garments.

The manufacturer chooses fabrics based on their comfort, durability, and functionality. The options are cotton pique, T/C blends, and knitted performance materials. Junesty fabric makes it a point to perform strength tests, control shrinkage, and colour fastness.

With low MOQs, adjustable production schedules, and rapid sample production, the company can help expand brands and businesses that require production flexibility due to changes in demand caused by seasons. Junesty performs multiple quality control checks during sewing, finishing, and packing. Along with their efficient export, they provide timely deliveries, which is one of their strongest assets.

Leeline Sportswear has a global clientele of manufacturers in the field of sports and activewear, along with polo shirt production. The company is reputed for its professional and advanced production systems that ensure precision in every garment produced.

From the range of materials: polyester knits, cotton blends, performance meshes, and elastic fabrics, the supplier has to offer, enabling buyers to select from polo shirts suited to and distinctively packaged for athletic, casual, and/or promotional usages.

Leeline accommodates different designs of the polo shirt, ranging from athletic-fit polo and corporate uniform variations. The factory adjusts to different regional markets and their size to complex print-demand and embroidery orders. The brand focuses on providing clients with delivery and production deadlines. Their delivery is reliable, even for international clients.

Custom apparel manufacturing, including premium polo shirts for established fashion brands and retailers, and the uniform industry, is a segment Ganci Clothing has initiated. Voluminous attention and care have established the company a reputation for finished garments with smoother details.

High-quality cotton blends, structured pique knits, and performance-enhanced fibres are often the materials the manufacturer works with. These fabrics are durable and provide a polished, comfortable, and classy look, perfectly aligning with a retail-quality polo shirt.

With the ability to respond to design changes, size order variations, and the need for custom branding, Ganci Clothing is nimble. Their production system excels in accurate colour matching, logo placement, and stitching. The company’s structured supply chain allows for predictable delivery and systematic implementation of international fulfilment. Customers enjoy seamless order delivery, efficient order communication, and prompt fulfilment.

China's apparel industry is growing rapidly. This is because of the improvement of industrialisation, government encouragement, and technology investment. The production of polo shirts is a great example of this advancement. Apparel manufacturing has implemented computerised knitting machines that produce the same uniform textures and digital cutting tools that waste less fabric. Companies have also begun to use embroidery machines that place logos more accurately and embroider with more detail.

China's position in the world is more powerful because of this technological advancement. China exports millions annually to the U.S., Europe, Asia, and the Middle East. China has also developed athletic-fit polos, slim-fit polos, corporate uniform polos, and eco-friendly polos. The experience with technology and varying products keeps driving this industry forward.

An additional factor contributing to the swift expansion of the industry is related to the abundance of qualified personnel and seasoned professionals. With China's long-standing history in textiles, the workforce has undergone training in the selection of fabrics, collar shaping, techniques of stitching, and finishing of garments. Such mastery guarantees uniformity in quality, even when dealing with bulk orders. There is also a strong infrastructure that includes, but is not limited to, high-quality, reliable and prompt international shipping with the presence of ports, logistic centres, and export facilities.

Ranging from the services offered to the level of quality offered, there is an equal level of satisfaction among customers from all parts of the globe. Perhaps one of the most remarkable is the capacity of the customer to maintain superior quality fabrics. In terms of textile fabric quality, the country has an abundant cotton yarn, polyester variety and even performance fabrics. Such a level of quality is made easier with the presence of locally accessible textile mills.

There is also an exceptional level of Customisation. Chinese factories present variations on designs to be made on order. It is such flexibility that is most appreciated by private label brands, uniform companies, and other promotional apparel. Be it to provide classic or sport or school uniform or even trendy apparel, Chinese manufacturers promptly adjust.

Several suppliers offer small minimum order quantities (MOQs) in order for newer brands to test the market prior to purchasing larger quantities. At the same time, these factories have the capacity to handle large bulk orders from big players in the industry. Their ability to scale production and meet client needs promptly makes them appealing to all buyers.

Reliability and consistency are also big reasons why these companies chose to source from these companies. Factories implement a timetable and provide open lines of communication regarding production, and provide updates throughout the process. For multiple stages in the process, quality control teams are employed to check for fabric weight, colour, stitching, and overall finishing of the garment. These partnerships help companies mitigate risk and build relationships based on trust.

Before buyers decide on what polo shirt manufacturer to use, there are a number of factors that have to be taken into account. One of the most important factors to consider is the fabric quality. Businesses are on the lookout for materials that are reflective of the brand standards, whether it is breathable cotton, high-strength polyester, performance knits, or eco-friendly blends, etc. The overall comfort of the fabric and how long it will last hinges on the texture, colour, durability, the weight of the fabric and many more.

Manufacturers’ capacity to produce consistently and reliably over time is essential as well. Buyers look for the capacity to produce thousands of units with a tight deadline and provide sample development. Factories with a qualified workforce and modern machinery produce expected results more often and reliably.

The availability of customisation also affects decision-making. Specific features are often sought by a lot of brands, including reinforced collars, ribbed cuffs, double stitching, heat-transfer labels, and embroidery. Accurate execution of these details is only possible with sufficiently advanced equipment and qualified personnel.

The presence of quality control is also very important. Buyers seek verified quality inspections that consist of control over raw materials, ongoing processes, and the finished garment. Desirable factories offer a well-organised document flow, packaging, and shipping, keeping consistent communication to avoid problems.

The reliability of delivery is also a very important factor. International buyers are highly dependent on predetermined delivery times, packing, and shipping offered by delivery policies. Manufacturers who are reputed to deliver on time are more likely to establish working relationships with international clients.

Evaluating these factors fabric quality, customisation, production flexibility, quality control, and delivery consistency, allows buyers to select these polo shirt manufacturers to meet their business objectives, product requirements, and long-term sourcing strategy.

The quality of the materials used in the construction of the polo shirt affects the overall life span of that shirt and the level of comfort it provides for the wearer. Given the long periods of time a polo shirt is worn, it is essential that the construction fabric is soft, breathable, and maintains its wear characteristics, especially its shape and size, over time. Blended cottons and performance materials that are moisture-wicking are a great choice. Quality materials will not only enhance the aesthetic of the shirt, but also the overall structure. If a manufacturer uses inexpensive materials, it will show in the rapid wear of the garment and the subsequent returns due to dissatisfaction. Selecting a good polo shirt manufacturer that is willing to spend the money to use quality materials will enhance the value of the shirt for the customer and maintain the brand image.

The sewing and finishing of a polo shirt greatly influence the strength, look, and durability of the item. A reputable manufacturer understands the importance of carefully attending to seams, collar construction, cuff closures, button placement, and hem lines. Well-executed stitching also aids in preventing garment fraying and helps the shirt retain its original size and shape. Techniques such as double stitching and detailed computerised embroidery help enhance the durability and visual appearance of the garment. Attention to detail finishing indicates a comprehensive approach to the manufacturing process, and that each garment produced is of the same quality. Well-executed stitching is more than a decorative detail; it forms the foundation of a comfortable, durable, and well-constructed polo shirt that can be produced for a variety of markets.

Being able to customise products is one of the ways companies can benchmark themselves from the competition. A competent manufacturer of polo shirts can provide services such as embroidered logos, printed artworks, woven labels, branded tags, and bulk packaging. These techniques allow businesses to convey branding identity and operational visibility while satisfying certain retail and corporate needs. Other additional design features, such as collar styles, button options, and sleeve styles, also help enhance the garment’s overall uniqueness. A manufacturer able to provide agile, comprehensive customisation services helps companies offer consistent branding and professional product styling to their targeted markets.

Production flexibility is vital for businesses, regardless of their company size. Growing and new businesses benefit more from manufacturers who can accommodate size-varied orders, be it small, medium, or even large. Strong brand and manufacturer partnerships are built via effective communication, more efficient production processes, and streamlined logistics. Such manufacturers who have production systems and processes calibrated to meet flexibility demands can avoid delays when it comes to sampling, custom order modifications, and orders that require repetition. They make it easier for businesses to remain competitive, move their stock. And quickly meet demands in a highly volatile market.

A manufacturer's experience has a major impact on the quality of the product, the accuracy and dependability of production, and the reliability of the manufacturer. An experienced manufacturer in this niche understands how different fabrics behave, the various ways of constructing a polo shirt, and what the market demands are. Certifications such as ISO, OEKO-TEX, and other certified Environmental compliance attest that the manufacturer has met the very basic requirements concerning safety, sustainability, and quality control and therefore met the minimum global requirements. Collaborating with certified and experienced manufacturers is a sure way to mitigate risks and deliver highly reputable garments.

For international customers, effective after-sales support and shipping are crucial. A professional manufacturer is transparent regarding the production schedule, packaging, and export papers. Implementing safe shipping practices ensures the order is intact and undamaged. Support after the sale is also necessary and includes complaint acknowledgement, quality concern resolution, returns processing, and reorder instructions. Efficient after-sales service shows a manufacturer’s dedication to sustaining partnerships and client satisfaction.

Top manufacturers of polo shirts separate themselves from the rest by combining appropriate material choices, artisan-level skill, modern production systems, and outstanding customer service. Diversifying their offerings is in line with the quality international market expectations. Professional manufacturers are instrumental to the sustainable growth of businesses by offering diversified product offerings, quality consistency, and prolonged customer reliability. Combined with their industry experience and state-of-the-art resources, seamless production for polo shirts is made effortless. This is why established manufacturers are the top choice for brands with polo shirts to produce.

A polo shirt's fabric quality will be a major determinant in its comfort, durability, and longevity. High-grade and performance fabric blends will prevent shrinking, fading, and discomfort during wear while maintaining their shape after repeated use.

Brands and manufacturers both need to look for quality features in sewing, like smooth stitching, reinforced hems, well-structured collar attachments, and strong fabric buttons. Good quality sewing will guard textiles against fraying and should help shape retention over time.

Most manufacturers of any level offer customisation such as embroidery, branded and/or custom artwork and packaging, and simple tags. Such branding is a major differentiator.

Yes, businesses require production flexibility for both small and large orders. This gives small and emerging businesses the capacity to control design iteration and production to match line inventory.

All certification processes, such as ISO and OEKO-TEX, evidence that an organisation and its manufacturer manage their operations to varying internationally recognised standards. Each certification adds value in the finished product’s field, engineered for trade and regulatory compliance.

Buyers need to know about the timeline, the way items are packaged, delivery safety and export documentation. After-sales services must cover assistance with clients' complaints, returns, reorders, and quality questions.

A professional producer offers consistent quality, an appropriate selection of materials, customisation, and efficient production processes. These factors enable brands to keep a reputation for quality and to add products to their lines.

Providing consistent quality, communicating openly, and being adaptable to order size are all attributes of a polo shirt manufacturer that will grow to be a long-term business partners. The above-listed attributes enable brands to keep their market demand.